VMC CASE STUDIES

Some of our best work in more detail!

Case Study: Revitalising a Smart ForTwo Brabus EngineValve Cover with Vapour Blasting – Vapour Modified Components Ltd

At Vapour Modified Components Ltd, we pride ourselves on

restoring automotive parts to their optimal state using our advanced vapour

blasting technology. This case study explores the stunning rejuvenation of a

valve cover from a Smart ForTwo Brabus engine, demonstrating the outstanding

outcomes delivered by our specialised cleaning process.

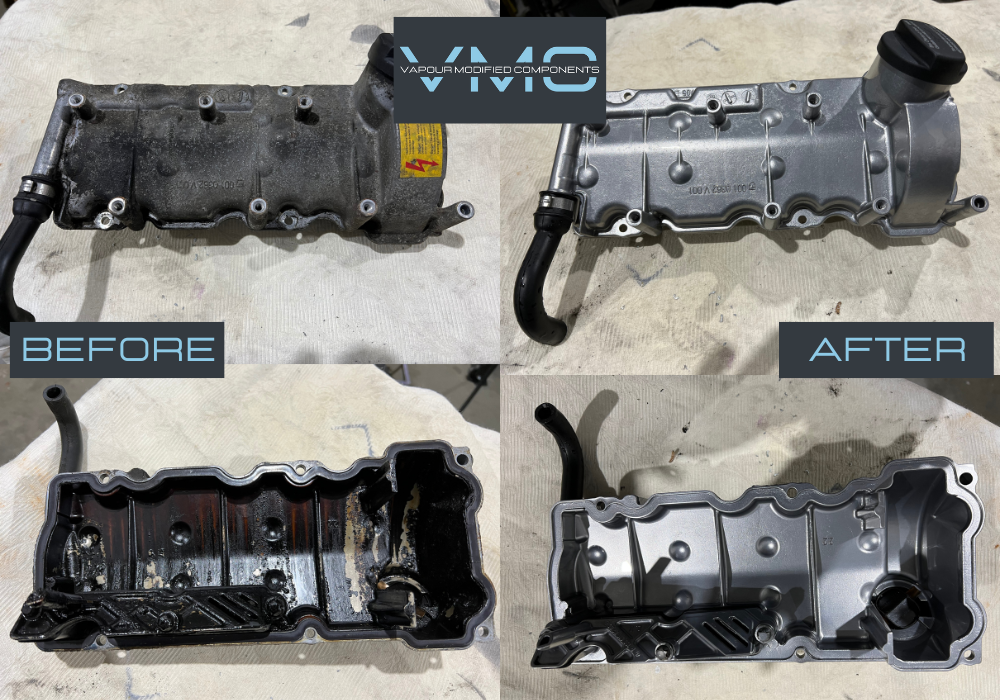

The Challenge: A Valve Cover Marred by Buildup

When the valve cover from a Smart ForTwo Brabus engine

reached our workshop, it was in a distressed state. The 'Before' photographs

reveal a component heavily coated with oil sludge, carbon deposits, and

accumulated dirt from prolonged use. This contamination not only compromised

the part’s appearance but also risked impairing engine performance by

potentially causing oil leaks or clogging critical areas. The valve cover’s

aluminium surface, once bright and smooth, was dulled and obscured by dark,

greasy residue, particularly around the bolt holes and internal surfaces.

The challenge was to remove this stubborn buildup

effectively while preserving the valve cover’s delicate structure and precise

tolerances. Conventional cleaning methods, such as dry blasting or harsh

chemicals, posed risks of surface damage or residue contamination, making them

unsuitable. Our vapour blasting expertise offered the perfect solution for this

delicate task.

The Solution: Precision Vapour Blasting by Vapour

Modified Components Ltd

At Vapour Modified Components Ltd, we utilise a

sophisticated vapour blasting technique that blends water, compressed air, and

fine abrasives to deliver a gentle yet powerful clean. This eco-conscious

method uses a wet blasting approach to strip away contaminants while

maintaining the integrity of the component, leaving a polished, uniform finish

without any surface distortion.

Our expert team carefully positioned the valve cover in our

vapour blasting cabinet, ensuring full access to all areas. We directed a

controlled mixture of water and abrasives onto the surface, targeting the oil

sludge, carbon, and dirt with precision. The water component minimised heat and

friction, while the abrasives effectively removed the buildup, reaching even

the most intricate internal cavities and external features without harming the

aluminium. This meticulous process restored the valve cover to its original

condition without compromising its functionality or longevity.

The Results: A Flawless, Restored Component

The ‘After’ images showcase a remarkable transformation. The

valve cover now boasts a brilliant, polished finish, with its aluminium surface

restored to a mirror-like sheen. Every trace of oil, carbon, and dirt has been

eradicated, revealing a pristine, smooth surface across all areas, including

the bolt holes and internal channels. This thorough cleaning not only enhances

the aesthetic appeal but also ensures optimal sealing and engine performance by

eliminating potential blockages and leaks.

The outcome is both visually impressive and functionally

superior, with the valve cover now free of contaminants and ready for immediate

use. Our vapour blasting process leaves no residues or abrasives behind,

guaranteeing a safe, high-quality result that supports long-term engine health.

Conclusion: Exceptional Results from Vapour Modified

Components Ltd

This case study underscores the unparalleled skill and

technology at Vapour Modified Components Ltd in bringing automotive components

back to life. By applying our innovative vapour blasting process, we

transformed a heavily soiled Smart ForTwo Brabus valve cover into a flawless,

high-performing part. Our dedication to precision, sustainability, and customer

satisfaction ensures that every component we treat achieves the highest

standards of quality.

To learn more about our services or to explore how we can

restore your automotive parts, visit our website at www.vapourmodifiedcomponents.co.uk.

Vapour Modified Components Ltd is committed to delivering exceptional results,

ensuring your vehicle operates at its peak performance.

Vapour Modified Components Ltd – Breathing New Life into

Your Engine Components.

Case Study: Restoration of a VW 1.9 TDI TransporterEngine Intake Manifold by Vapour Modified Components Ltd

At Vapour Modified Components Ltd, we specialise in

revitalising automotive components through our state-of-the-art vapour blasting

process. This case study highlights the remarkable transformation of an intake

manifold from a VW 1.9 TDI Transporter engine, showcasing the exceptional

results achieved through our meticulous cleaning techniques.

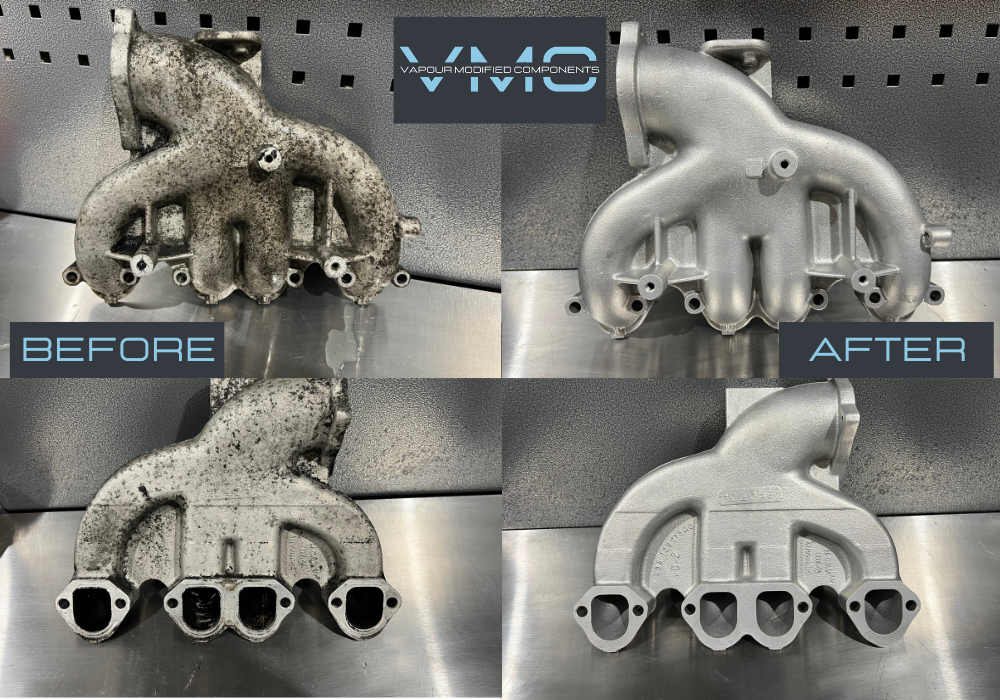

The Challenge: A Heavily Contaminated Intake Manifold

The intake manifold, a critical component of the VW 1.9 TDI

Transporter engine, arrived at our facility in a severely degraded condition.

As depicted in the ‘Before’ images, the manifold was encrusted with layers of

carbon deposits, oil residue, and general grime, accumulated over years of

service. These contaminants not only marred the aesthetic appeal of the part

but also posed potential performance issues, such as restricted airflow and

reduced engine efficiency. The manifold’s original metallic finish was

obscured, with dark, uneven patches covering its surfaces, particularly around

the ports and intricate curves.

The task at hand required a cleaning method that could

delicately yet effectively remove the stubborn buildup without damaging the

manifold’s aluminium structure or compromising its dimensional accuracy.

Traditional cleaning methods, such as abrasive blasting or chemical soaking,

risked altering the part’s integrity or leaving harmful residues. This is where

our expertise in vapour blasting proved invaluable.

The Solution: Vapour Blasting by Vapour Modified

Components Ltd

At Vapour Modified Components Ltd, we employ a precision

vapour blasting process that combines water, compressed air, and fine abrasives

to gently yet thoroughly clean components. This environmentally friendly

technique uses a wet blasting method to create a smooth, uniform finish while

eliminating contaminants without causing micro-abrasion or surface distortion.

Our skilled technicians carefully prepared the intake

manifold, ensuring it was securely positioned within our vapour blasting

cabinet. The process involved directing a controlled stream of the

vapour-abrasive mixture across the manifold’s surfaces, targeting the carbon

deposits, oil residues, and grime with precision. The water in the mixture

acted as a lubricant, reducing heat and friction, while the abrasives

effectively stripped away the buildup. This method allowed us to clean even the

most intricate areas of the manifold, including the internal ports and external

contours, without compromising the part’s structural integrity.

The Results: A Pristine, Like-New Finish

The ‘After’ images tell a compelling story of

transformation. The intake manifold emerged from our vapour blasting process

with a gleaming, mirror-like finish, restoring its original aluminium lustre.

The carbon deposits, oil residue, and grime were completely eradicated,

revealing a clean, smooth surface free of imperfections. The ports, once

clogged and darkened, now showcased clear, unobstructed openings, ensuring

optimal airflow and engine performance.

The results were not only visually striking but also

functionally superior. The manifold’s restored condition enhances its

durability, prevents future contamination buildup, and contributes to improved

engine efficiency. Our vapour blasting process left no residual abrasives or

chemicals, ensuring the part was ready for immediate reinstallation without

additional treatment.

Conclusion: Unparalleled Expertise at Vapour Modified

Components Ltd

This case study exemplifies the exceptional capabilities of

Vapour Modified Components Ltd in restoring automotive components to their peak

condition. Through our innovative vapour blasting process, we transformed a

heavily contaminated VW 1.9 TDI Transporter intake manifold into a pristine,

high-performing part. Our commitment to quality, precision, and environmental

responsibility ensures that every component we handle meets the highest

standards.

For more information about our services or to discuss how we

can restore your automotive components, please visit our website at www.vapourmodifiedcomponents.co.uk.

At Vapour Modified Components Ltd, we take pride in delivering outstanding

results that exceed expectations, ensuring your vehicle performs at its best.

Vapour Modified Components Ltd – Revitalising

Performance, One Component at a Time.